3D Printing 04 (PLA): Glutton for Punishment

Expanding

The next hardware issue I had was after a filament run out. It was a print I had only started because I knew how empty the spool was and I just wanted to test the best print orientation on a model that was quite intricate. After the filament run out sensor halted the print I just abandoned it.

It wasn't until the next time I tried to print that I found out the first layer wouldn't start. The printer kept freezing while doing the Cura primer line and just sat there with "Processing" on the screen.

It took me a couple of attempts while watching it closely to realise that the run out sensor was tripping for a split second and then coming back on again. I had my usual panic attack at this and ordered about 8 different replacements just to make sure I got one that worked. Then I calmed down, had a think and took the old one to pieces. I bent the spring-loaded arm slightly to increase the tension and it has worked ever since.

So, my printer can now get through a four day printing session without self harming. I've printed something like five more madalorian helmets of various sizes that all came off in one piece. Also some armour. I therefore decided to tackle my brand new print quality problems. Parts of my helmets (always the same regions) looked like they had been knitted instead of 3D printed. My spray putty wouldn't cover the holes no matter how many coats I put on. I think it was running down inside the helmets because they began to feel like garden ornaments as they were so heavy. Good luck wearing them! At least they might protect you almost as much as Beskar. In fact I'd started spraying the putty into the lid of the tin and brush painting it on the worst areas as a pre-treatment.

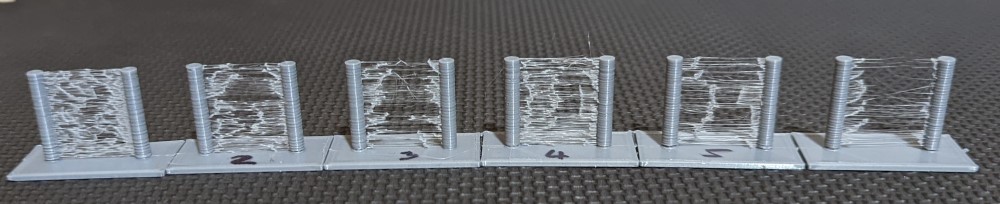

I'd seen the term "under extrusion" on web sites usually accompanied by questions about your flow, which I thought a bit intrusive. I Googled "under extrusion" and found pictures that looked just like the problem areas of my helmets. Long story short, this was a speed issue. Wiping out my speed settings in Cura and restoring the defaults highlighted that I had at some point thought that if my print speed was 80, then all the settings should say 80. The defaults showed me that walls and stuff should be at a slower speed.

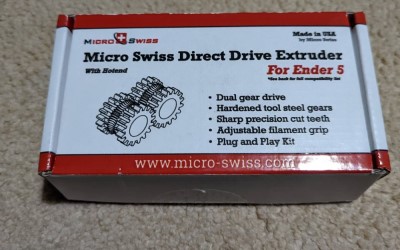

Okay, it has been many months since I started this article and I've lost my train of thought a bit. My Ender 5 Plus has been printing nicely except for when the hot end filled with a tar like substance a couple of times so I eventually swapped it out for a Micro Swiss all metal hot end. There was an instant increase in print quality although, even though I'd heard you have to increase the nozzle temperature 10 degrees, the stringing I was seeing suggested I had to decrease it instead. That didn't go well as it led twice to the filament refusing to extrude two days into long prints. I therefore increased the temperature after all and decided I could put up with the stringing.

The last issue I'll mention here before just ending this rather unpolished article is (I think) a Cura software issue. I printed a mando helmet and noticed it had two fault lines midway up the print about two inches apart. I noticed them, but only in terms of noting something I was going to have to smooth out. Imagine my surprise when, while I was merrily sanding it, the helmet exploded in my hands.

Well, that's what it felt like anyway. The print ripped in half so suddenly under pressure that one half flew over my head and I almost soiled my trousers. Fortunately, I'm a dab hand at sticking these things together now so I dealt with it.

The very next print was the same helmet from the same GCode and it had the very same two lines in the same places. I cautiously twisted it a bit and it ripped only halfway round this time like it was perforated for easy separation. On almost the same day this happened, I watched a "Frankly Built" YouTube video where he talked about glitches in Cura where sometimes one solitary layer will jump randomly to the wrong place. I'm only guessing this is what happened, but I rarely use the same GCode twice now whereas I used to keep a library of them.

So, that's it I'm abandoning this article that's been sitting unfinished all this time. I've been on Instagram more than here lately and I bought a second printer; a Tenlog TLD 3 Pro, which gives me dual extruding printing abilities. I'd printed and painted so many helmets that the quality was becoming pretty stunning, even if I do say so myself, and they were fetching a decent price on eBay so it seemed natural to supplement my printing capabilities.

Soon after that, believe it or not, I scooped top prize in a local lottery. I got a couple of thousand pounds and bought a third 3D printer, a Mars 3 resin printer, which pleased my son no end because we had spent months wondering why the D&D miniature STLs he'd paid for just wouldn't print at all well on the Ender.

And... now I realise I have ideas for another article or two.